Air Source Heat Pump

In May 2021 we waved goodbye to our heating oil tank and oil-powered central heating boiler and replaced them with a state-of-the-art Air Source Heat Pump (ASHP).

In May 2021 we waved goodbye to our heating oil tank and oil-powered central heating boiler and replaced them with a state-of-the-art Air Source Heat Pump (ASHP).

We had researched ASHP technology for 12 months or so and acquired information and a quotation from a major renewable energy installer. Our primary driver was the environment and reducing our impact on it. We also visited two installations in neighbouring homes in our village, one installed 2012, the other in 2019 and listened to the owners' comments and suggestions. We followed a strong recommendation from one of the neighbours to use Regen Renewables ![]() ,a Midlands-based renewable energy installation company specialising in ASHPs and Solar installations with many years of expertise in the field.

,a Midlands-based renewable energy installation company specialising in ASHPs and Solar installations with many years of expertise in the field.

The unit selected is a Hitachi 14KW LW Split Air Source Heat Pump.

A 4-hour meeting with them at our home provided a comprehensive explanation of heat pumps, their applicability to our building and the costs and benefits. Within a week the building had been forensically analysed to determine what the heat requirements were for each room and the planned changes that would be required to our wall-hung radiators to make them most effective. A single lump sum price was presented to include the technology units, installation, new radiators throughout, VAT and all RHI (Renewable Heat Incentive) government incentive payment paperwork. The economics over a 7-year period suggested that the net additional cost of clean heating would be acceptably more than a new £5,000 oil boiler would have cost.

The installation by the plumbing and electrical teams took 4 days in 6 main stages;

- replace all radiators

- replace the 57-year old airing cupboard hot water cylinder with a hi-tech beauty

- install the heat pump's fan unit on a base in the garden.

- install the compressor unit on the gable end wall of the attic

- connect the cabling between the three main components

- remove the wall-hanging old oil fired boiler

We were delighted with the professionalism and helpfulness of the installation teams. However the initial handover, instructions, user manuals and post sale support have a long way to go to make the control of the system easier and more effective to manage.

Our ASHP Performance

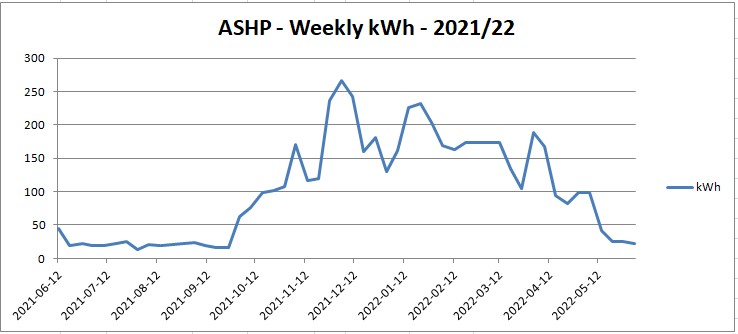

The system was solely used for Hot Water for 30 minutes a day (July - September), and it was only in October that the space heating was initialised. At the end of 52 weeks, the energy consumption was compared between the previous year's use of Heating Oil and the first year of using the Air Source Heat Pump.

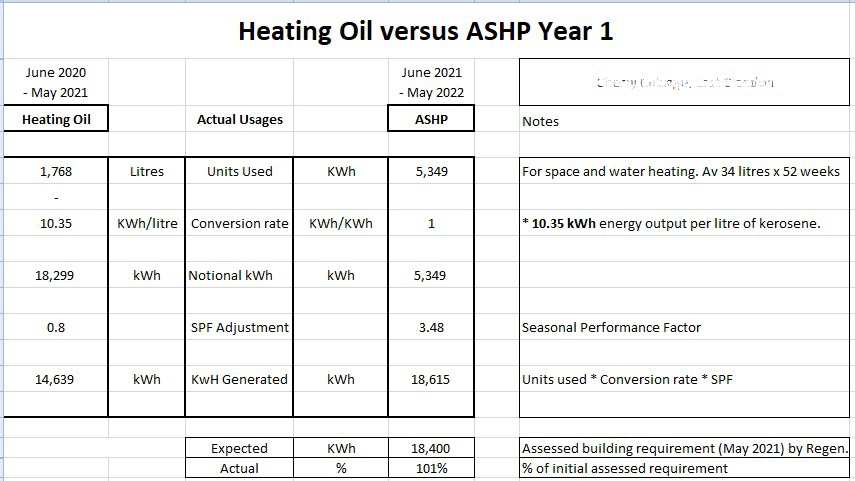

The table below shows the predicted heating requirement of the buidling (assessed before installation) of 18,400 kWh was met and exceeded by just 1% using the ASHP. While the oil had provided the same value in consumption, due to its lower SPF it had only delivered 14,639 kWh of heat.

Forward costing the respective annual energy consumptions based on known unit pricing at June 2022, the two fuels would be the same cost, but:

- The Oil system generates less kWh in heat into the house than the ASHP.

- The ASHP provides quieter, cleaner and more consistent heating through the radiator system.

- The environment benefits from the absence of burning 1,768 litres of oil.

We installed it for environmental reasons. Overall the ASHP works very effectively, is no more expensive to operate than the oil system it replaced and has provided us with a more peaceful building and more consistent and efficient heat throughout the building. The downside is the 1 - 2 year learning curve of how to manage its various configurations and settings. In this respect we expect to be 10% more electricity efficient in Year 2. This technology has now got us close to net zero CO2 emissions.